Custom Safety Nets – Your Reliable Solution for Secure Protection

Custom safety netting is essential for construction sites, sports facilities, warehouses, and industrial zones to prevent falls, contain debris, and protect people. At Wenneting, we tailor high-strength, durable nets to your exact needs—whether for heavy-duty construction barriers, sports field enclosures, or warehouse safety partitions. With 25 years of expertise, we ensure your netting meets strict safety standards while fitting your unique requirements.

Safety Netting Sub-Categories

Construction Safety Netting

Personal Fall Protection Netting

Scaffold /Debris Safety Netting

Cargo Safety Netting

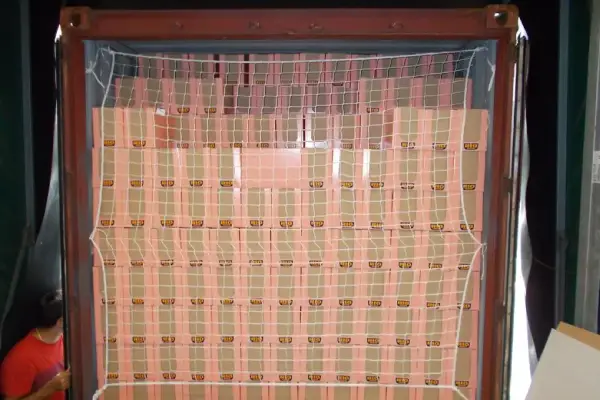

Tailored to Your Needs: Color & Branding Customization

Stand out with branded safety nets that reinforce professionalism. We offer OEM/ODM services, letting you choose colors (e.g., high-visibility orange for construction) and add logos/patterns for brand consistency. Why settle for generic when your netting can reflect your company’s identity? Ideal for contractors and sports venues needing cohesive site aesthetics.

Strength That Matches Your Demands: Material & Mesh Customization

Not all hazards are the same—your netting shouldn’t be either. Select from UV-resistant polyethylene, nylon, or steel-core nets with adjustable mesh density (fine for debris, wide for ventilation). Our ISO-tested materials undergo batch checks for tensile strength , ensuring long-term durability even in harsh weather.

Fast & Flexible: Small-Batch Orders & Rapid Delivery

Need 500 units or 5,000? We accommodate small orders without minimums, perfect for trial runs or urgent projects. With 5,000㎡ of stocked inventory and FedEx/DHL partnerships, we ship globally in 15–20 days. No more delays—just reliable nets, exactly when you need them.

Looking for high-performance divider netting and safety netting solutions that combine durability, safety, and customization? Wenneting is your trusted partner! With 25+ years of expertise in manufacturing premium sports barrier nets, batting cages, and industrial safety nets, we help gyms, warehouses, children’s playgrounds, and sports facilities enhance safety, optimize space, and reduce costs.

- Tailored Solutions: Customize nets by size, color, material, and branding (OEM/ODM) to fit your exact needs.

- Unmatched Quality: High-strength polyester/polypropylene nets, rigorously tested for UV resistance, tensile strength

- End-to-End Support: From free samples to logistics, we streamline global procurement for traders and end-users alike.

THE ULTIMATE GUIDE

Custom Safety Netting : Applications, Types and Installation

Safety netting is a critical component in various industries and residential settings, providing essential protection against falls, debris, and other hazards. Custom safety netting, tailored to specific dimensions, materials, and applications, offers unmatched versatility and reliability. This comprehensive guide explores the types of custom safety netting, their applications, customization options, and a detailed installation guide to ensure optimal safety and performance.

Introduction to Custom Safety Netting

Safety netting serves as a protective barrier to prevent injuries and damage caused by falling objects or people. Unlike standard netting, custom safety netting is designed to meet the unique requirements of a project, ensuring a precise fit and enhanced functionality. From construction sites to sports facilities and residential homes, custom safety netting adapts to diverse environments, offering peace of mind and compliance with safety regulations such as OSHA, ANSI, and EN standards. This article delves into the types of safety netting, their applications, customization possibilities, and step-by-step installation guidance.

Types of Custom Safety Netting

Custom safety netting comes in various forms, each designed for specific purposes based on the environment, hazard, and intended use. Below are the primary types of safety netting and their characteristics.

1. Personnel Safety Nets

Personnel safety nets are designed to protect workers from falls, particularly in high-risk environments like construction sites, bridges, and industrial facilities. These nets are typically made from high-tenacity materials such as nylon, which offers a high strength-to-weight ratio and elasticity to absorb impact. They comply with standards like EN 1263-1 and OSHA 1926.105, ensuring they can withstand falls from heights up to 30 feet. Key features include:

- Material: High-tenacity nylon (e.g., Type 6,6 nylon) with UV resistance to prevent degradation.

- Mesh Size: Typically 120mm for industrial-grade applications to balance strength and visibility.

- Applications: Construction sites, bridge construction, roofing, and high-rise buildings.

- Certifications: EN 1263-1 System S, DGUV 101-011, and ANSI A10.11 for fall protection.

Personnel safety nets are critical for protecting workers on elevated platforms, scaffolding, or open edges, providing a softer catch compared to rope anchors while maintaining freedom of movement.

2. Debris Safety Nets

Debris safety nets are engineered to catch falling objects, such as tools, construction materials, or lightweight debris like coffee cups and pens. These nets are essential for protecting pedestrians, workers, and property below work zones. They come in single- or multi-ply configurations depending on the debris size and weight.

- Material: PVC-coated polyester for lightweight debris; two-ply systems with polypropylene webbing for heavier debris like bricks or concrete chunks.

- Mesh Size: 1/8” x 3/16” for light debris; 3/8” or 2” for heavier objects.

- Applications: Construction sites, demolition projects, open-pit covers, and window protection.

- Breaking Strength: Up to 1,200–2,000 lbs for heavy-duty systems.

For example, InCord’s two-ply debris netting system combines a structural net with a finer liner to handle both large and small debris effectively.

3. Sports Netting

Sports netting is customized for athletic facilities to contain balls, protect spectators, and enhance safety during games. These nets are tailored to specific sports, with mesh sizes and materials varying based on ball size and impact force.

- Material: Nylon, polyester, or polypropylene, chosen for durability and weather resistance.

- Mesh Size: Tighter meshes (e.g., 20mm) for field hockey; larger meshes (e.g., 100mm) for soccer.

- Applications: Baseball fields, soccer arenas, hockey rinks, golf courses, and backyard sports courts.

- Customization: Available in club colors, two-tone designs, or retractable systems.

Safetynet365 and All Sport Netting offer custom sports netting that can be designed for indoor or outdoor use, ensuring compliance with sports safety standards.

4. Home Safety Nets

Home safety nets are used in residential settings to prevent falls from balconies, staircases, mezzanines, or pools. These nets are often designed for aesthetic appeal as well as functionality, blending seamlessly with home decor.

- Material: UV-resistant nylon or polyester for durability in outdoor conditions.

- Mesh Size: Varies based on application (e.g., finer meshes for child safety).

- Applications: Balconies, staircases, trampolines, and pool covers.

- Customization: Available in various colors and shapes to match home aesthetics.

For instance, Loftnets provides home nets that double as guardrails or catamaran-style trampolines, offering both safety and recreational value.

5. Industrial and Warehouse Netting

Industrial netting is used in warehouses, manufacturing facilities, and distribution centers to prevent objects from falling off conveyors, pallet racks, or mezzanines. These nets enhance workplace safety and comply with OSHA standards.

- Material: Polyethylene or nylon with reinforced borders and grommets.

- Mesh Size: 1/16” for small items; larger meshes for heavier loads.

- Applications: Conveyor systems, pallet rack safety, mezzanine protection, and load-securing nets.

- Capacity: Standard nets support 1,250–5,000 lbs; custom designs handle heavier loads.

US Netting’s mezzanine and conveyor netting solutions are OSHA-compliant and designed to prevent both personnel falls and falling objects.

6. Specialty Nets

Specialty nets include bird protection nets, load-securing nets for transportation, and environmental restoration nets. These are highly customizable to fit unique applications.

- Material: Polypropylene for bird nets; nylon for load-securing nets.

- Mesh Size: 8mm–300mm, depending on the application.

- Applications: Agriculture, transportation, and ecological restoration.

Safetynet365 offers finer bird protection nets and robust goods protection nets for industrial needs.

Applications of Custom Safety Netting

Custom safety netting is versatile and used across various sectors. Below are key applications:

1. Construction and Bridge Building

Safety nets are indispensable in construction to protect workers and pedestrians from falls and falling debris. Horizontal perimeter nets are used under roofs or bridges, while vertical nets surround scaffolding or open edges. For example, FallProof’s horizontal perimeter systems are ideal for high-rise construction, and V-type safety nets from Aitana Safety create a “cage” for edge protection.

2. Sports Facilities

Sports netting ensures player and spectator safety by containing balls and preventing injuries. Custom nets are used in baseball, soccer, hockey, and golf facilities, tailored to specific dimensions and aesthetic preferences.

3. Residential Safety

Home safety nets protect children and adults from falls in high-risk areas like balconies, staircases, or pools. They are also used for trampolines and as guardrails for mezzanines, combining safety with aesthetic appeal.

4. Industrial and Warehouse Safety

In warehouses, netting prevents goods from falling off conveyors or racks, protecting workers and inventory. Mezzanine netting and hatch netting systems are critical for OSHA compliance in elevated work areas.

5. Transportation and Load Securing

Custom nets secure cargo in vehicles, preventing items from shifting or falling during transport. These nets are used in trucks, trailers, and boats, ensuring safety and compliance with transportation regulations.

6. Environmental and Agricultural Protection

Bird protection nets safeguard crops and gardens, while environmental restoration nets support ecological projects. These nets are customized to fit specific areas and withstand outdoor conditions.

Custom Options for Safety Netting

Custom safety netting offers a range of options to meet specific needs. Key customization aspects include:

1. Dimensions

Custom nets are manufactured to precise measurements, ensuring a perfect fit for any space, whether it’s a small balcony or a large construction site. Customers provide height, width, length, or square meter specifications.

2. Material

Common materials include:

- Nylon: High strength, elasticity, and UV resistance for personnel safety nets.

- Polypropylene: Lightweight, weather-resistant, and cost-effective for debris and sports nets.

- Polyethylene: Flexible, UV-resistant, and suitable for outdoor applications.

- PVC-Coated Polyester: Ideal for lightweight debris nets with finer meshes.

Material selection depends on durability, environmental exposure, and budget.

3. Mesh Size

Mesh sizes range from 8mm to 300mm, tailored to the application. For example:

- Smaller meshes (8–20mm) for bird protection or field hockey.

- Medium meshes (50–120mm) for personnel safety or soccer.

- Larger meshes (200–300mm) for heavy debris or cargo securing.

4. Color and Aesthetics

Custom nets can be made in various colors, including club colors for sports facilities or neutral tones for homes. Two-tone or colorful designs enhance visual appeal.

5. Border and Hardware

Borders can include reinforced rope, webbing, or grommets for secure attachment. Hardware options include hooks, clips, cables, outrigger poles, and slab grabbers for specific installation needs.

6. Certifications and Standards

Custom nets can be designed to meet specific standards, such as:

- EN 1263-1: For fall-arrest nets.

- OSHA 1926.105: For construction safety.

- ANSI A10.11: For personnel safety nets.

- DGUV 101-011: For European fall protection standards.

7. Special Shapes and Features

Nets can be crafted in unique shapes, such as triangular or circular, for irregular spaces. Features like retractable systems or central tensioning systems (CTS) enhance functionality.

Installation Guide for Custom Safety Netting

Proper installation is critical to ensure safety netting performs effectively. Below is a step-by-step guide based on industry standards and best practices.

Step 1: Planning and Preparation

- Assess the Site: Identify hazards, measure dimensions, and determine the type of netting needed (e.g., personnel, debris, or sports).

- Select Materials and Hardware: Choose nets and hardware (e.g., hooks, cables, brackets) based on the application and load requirements.

- Check Regulations: Ensure compliance with OSHA, ANSI, or EN standards. For example, EN 1263-1 System S nets require a minimum breaking energy and aging resistance.

- Prepare Written Instructions: Create a plan for installation, modification, and dismantling, as required by DGUV 101-011. Include net size, suspension points, and installation procedures.

Step 2: Clear the Area

- Remove obstructions and secure the installation zone to prevent unauthorized access.

- Construct temporary barriers if necessary to ensure worker safety during installation.

Step 3: Anchoring the Net

- Identify Suspension Points: Anchor nets to stable, load-bearing points capable of withstanding at least 6 kN at a 45° angle, spaced no more than 2.5m apart (Safetynet365 guidelines).

- Attach Hardware: Use hooks, clips, or slab grabbers to secure the net to anchors. For guardrail nets, anchor to scaffolding rails at 75cm intervals.

- Ensure Tension: Stretch the net taut to prevent sagging, using cables or ropes as needed.

Step 4: Specific Installation Methods

- Horizontal Perimeter Nets: Install under roofs or bridges using outrigger poles and cables. Test for cushioning to prevent rebound (FallProof).

- Vertical Nets: Attach around scaffolding or open edges, ensuring a tight fit to contain debris or prevent falls.

- Pool Nets: Use a central tensioning system (CTS) with a tensioning tool to apply even tension. Mark anchor points with twine or permanent markers for re-installation (All-Safe Pool).

- Sports Nets: Secure to poles or frames with turnbuckles for a tight fit, especially for high-impact sports like hockey.

Step 5: Testing the Installation

- Perform a drop test with a weight representing the maximum potential falling load (e.g., 400 lbs for personnel nets, as per ANSI standards).

- Ensure the net catches the weight without tearing or breaking.

- Check for proper tension and secure attachment points.

Step 6: Inspection and Maintenance

- Regular Inspections: Check nets weekly for signs of wear, UV degradation, or damage. Replace compromised sections promptly.

- Maintenance: Clean nets to remove debris and store them in a dry, rodent-free environment when not in use.

- Documentation: Maintain records of inspections, tests, and repairs to comply with safety regulations.

Step 7: Professional Assistance

- For complex installations, hire certified net fitters trained per DGUV 301-004 standards.

- Companies like FallProof and Guardian offer on-site supervisors to assist with installation, ensuring compliance and safety.

Benefits of Custom Safety Netting

- Precision Fit: Tailored to exact dimensions, ensuring maximum coverage and effectiveness.

- Enhanced Safety: Meets or exceeds industry standards, reducing the risk of injuries and damage.

- Versatility: Suitable for diverse applications, from construction to sports and home use.

- Durability: Made from high-quality, weather-resistant materials for long-term use.

- Aesthetic Appeal: Custom colors and designs blend with the environment.

Conclusion

Custom safety netting is a vital solution for protecting people, property, and equipment across various settings. By understanding the types of netting—personnel, debris, sports, home, industrial, and specialty—you can select the right solution for your needs. Customization options like dimensions, materials, mesh size, and colors ensure a perfect fit, while proper installation guarantees optimal performance. Whether you’re securing a construction site, a sports facility, or a home balcony, custom safety netting offers unmatched safety and reliability. Consult with Wenetting Custom Safety Netting Experts and get your Netting Solutions Now !

Get Instant Quote

Frequently Asked Questions

Every batch undergoes SGS/TUV-certified tests for tensile strength, abrasion resistance, and UV stability. We use high-density polyethylene (HDPE) or nylon with anti-aging additives to ensure long-term outdoor performance.

Yes! We specialize in non-standard dimensions, curved nets, and custom-cut panels for complex installations (e.g., stadium roofs, irregular scaffolding). Just provide drawings or specs, and we’ll engineer a solution.

Standard designs: 10–15 days. Complex customizations (e.g., special coatings/prints): 20 days max. Rush production is available for urgent needs.

Absolutely—no MOQ, so you can order as few as 1–10 nets for prototypes or small-scale deployments.

We partner with DHL/FedEx for fast air delivery (15–20 days globally) and support sea freight for bulk orders. All nets are compressed and palletized to save costs

Yes! Our nets meet EN 1263-1 (fall protection), ISO 9001, and OSHA guidelines. We provide test reports and compliance documentation upon request.

Of course—we weave, print, or stitch logos, tags, or QR codes directly onto the netting or packaging for brand visibility.

Yes! We supply installation manuals, anchor point recommendations, and 3D renderings—plus live video support for complex setups.

Stains: Mild soap + soft brush.

Storage: Dry fully before folding to prevent mildew.

Avoid pressure washers, which can damage fibers.

Get Free Sample

Our Custom Safety Netting Projects

Every project teaches us how to better serve you. Over the years, we’ve delivered custom safety nets for industries ranging from high-rise construction to international sports events. Our solutions are tested in real-world conditions—whether it’s extreme wind loads, abrasive environments, or strict compliance demands. When you partner with us, you’re not just buying nets; you’re leveraging 25 years of problem-solving expertise to mitigate risks and streamline your operations. More Projects